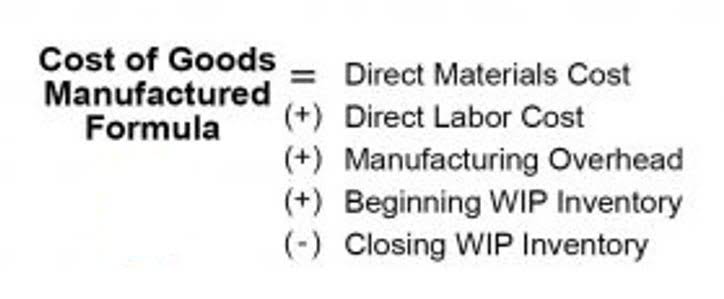

It includes all direct, indirect, fixed, and variable costs involved in the production of finished goods – for example, raw materials, labour costs, and daily consumables like screws and staples. Production costs encompass all expenses required to bring a product to the market, including direct materials, labor, and overhead. Manufacturing costs specifically relate to the expenses directly tied to creating goods, such as materials, labor, and factory overhead. online bookkeeping In essence, all manufacturing costs are part of production costs, but production costs also include broader expenses beyond manufacturing.

- Because there is no better way to automate manufacutirng then by ultilizing barcodes.

- Once you know your cost per unit, you can start adjusting production lines and margins to get that CPU down.

- To manufacture the tables, he must have raw materials, hours, and other equipment.

- Total cost of production includes the total manufacturing cost plus all additional indirect material and labor costs.

Developer costs

This might involve negotiating better terms with suppliers, improving operational efficiency, or scaling production. Keep in mind that any fixed or variable costs you include must get incurred while producing your product or service. Just add the total fixed costs from a specific period of time to the total variable costs over the same period. Indirect costs are not directly related to manufacturing and, therefore, generally remain the same period over period.

How production volume affects cost per unit

Each project is treated as a separate cost unit, and costs are recorded https://kofejob-wp.dreamstechnologies.com/best-ways-to-pay-instagram-influencers/ throughout its duration. It helps track progress, manage expenses, and determine profit at different stages. In accounting, product cost determines the value of closing inventory in the balance sheet.

A. Calculate Direct Materials Cost

- Through regular variance analysis, the manufacturer identified significant discrepancies in the overhead allocation.

- Calculating total cost is a critical analytical process for businesses, especially those in technology sectors characterized by rapid innovation, high capital expenditure, and evolving pricing models.

- It’s going to impact everything from the suppliers you use to the type of product or service you produce.

- This can give you the information you need to make informed decisions about accurately pricing products and choosing efficient production methods.

- Still, it is very difficult or insignificant to trace the low value of grease used in a particular vehicle hence referred to as indirect costs.

- As businesses grow and change, the demand for precise cost analysis and financial insights will stay strong.

- Our rigorous editorial process includes editing for accuracy, recency, and clarity.

Direct material cost refers to the cost of materials used in the manufacturing process. Businesses calculate this by adding the cost of material purchases to the cost of starting inventory and subtracting the cost of ending inventory. It’s important to factor in both your direct and indirect costs when using the total manufacturing cost formula.

Implications for Financial Planning and Pricing Strategies

This score implies that the crew was more efficient than expected, completing the project in less time than planned. This is a favorable variance, boosting productivity and reducing labor expenses. Return on Assets (ROA) assesses a company’s effectiveness in using its total asset base to produce profits. It measures the company’s overall performance and its ability to generate income from its assets. The ROA calculation involves dividing the firm’s net income by its average total assets.

Why the Total Cost Formula Matters

There are many ways to achieve this, but in today’s digital age, it typically means implementing manufacturing automation. Traditional methods allocate factory overhead cost total product cost formula based on a predetermined rate, such as dividing total overhead by total direct labor hours. Although this method is simple, it may lead to inaccuracies if the proportion of overhead varies across departments.